Bone deformities of the proximal extremity of the humerus can be degenerative or traumatic. Thanks to new technologies such as mediCAD® 3D Shoulder, the surgical advantages in the preoperative planning of inverse shoulder prostheses have been significantly improved. As a result, the implantation of inverse shoulder prostheses has increased significantly in the field of orthopedic surgery.

The shoulder is the joint with the largest range of motion in the human body, and for its good function, it is important that all articular and periarticular structures are in anatomical position. It is through the shoulder that humans perform most of their movements to go about their daily lives. The anatomy of the bone has a fundamental role as it is the basis for the origin and insertions of all other tissues such as cartilage, labrum, ligaments, muscles, and tendons. Any impact that alters the proper function of the bony framework causes a biomechanical imbalance with changes in joint congruency, length, and angulation of the muscles, resulting in shoulder girdle dysfunction that unfortunately can become a nightmare for many patients.

Fortunately, thanks to new technologies such as mediCAD® 3D Shoulder, the surgical advantages in the preoperative planning of inverse shoulder prostheses have been significantly improved. As a result, the implantation of inverse shoulder prostheses has increased significantly in the field of orthopedic surgery. Bone deformities of the proximal extremity of the humerus can be degenerative (osteoarthritis) or traumatic (fractures). Understanding the anatomic changes through imaging studies is extremely important for the proper treatment of these deformities. It is difficult, even impossible, to characterize changes in joint anatomy with conventional 2D radiographs.

Using mediCAD® 3D to better characterize changes in joint anatomy

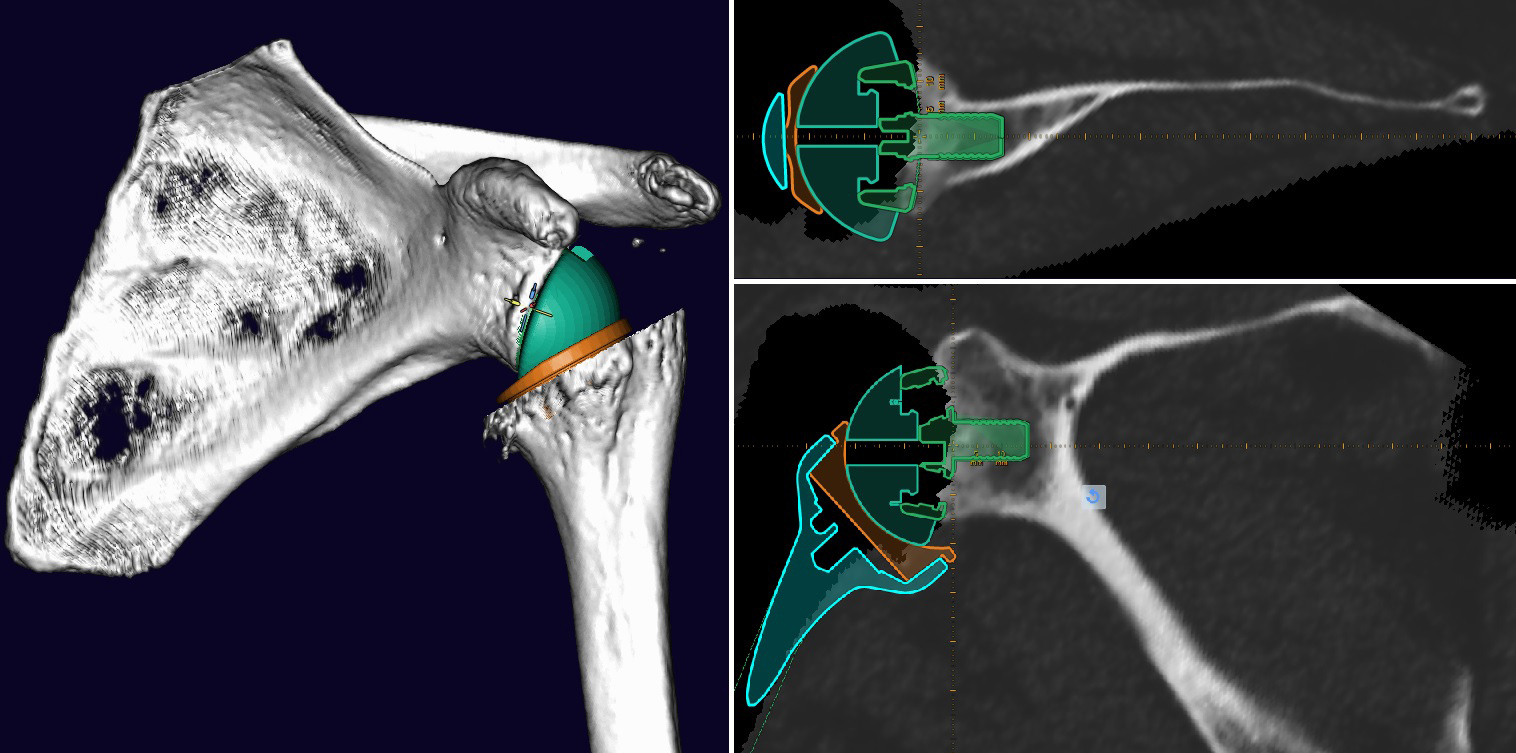

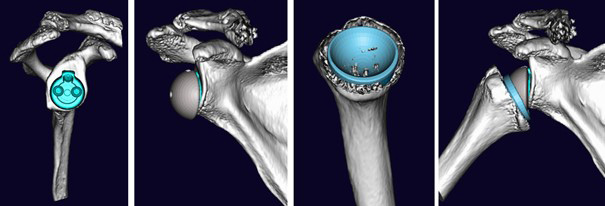

Using computed tomography in combination with mediCAD® 3D's patient specific three-dimentional reconstructions a more detailed assessment of bone anatomy is possible. A CT scan or computed tomography scan is a medical three-dimensional imaging technique that uses computer-processed combinations of multiple X-ray measurements from diverse perspectives to create tomographic images which provide a non-invasive view inside the body.

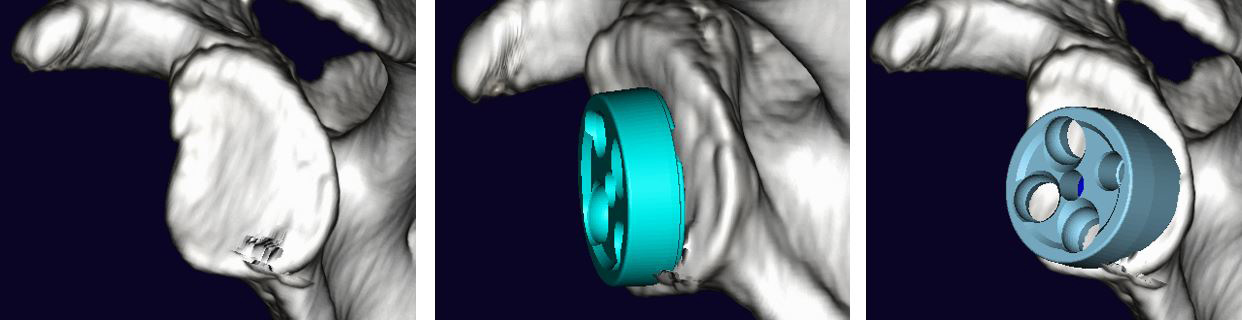

Rapid prototyping is a method of building real three-dimensional models from virtual three-dimensional models. Rapidly producing a physical part or model using 3D computer-aided design (CAD) helps orthopedic surgical teams obtain much more detailed information. With mediCAD®, the morphology of the humerus and glenoid can be better assessed and misplacement of implant components can be avoided. It reproduces an accurate three-dimensional copy of the bone anatomy in synthetic models.

Here is an overview of the advantages of using mediCAD® 3D Shoulder when planning an inverse shoulder prosthesis:

• More precise details of the bone pathology

• Better assessment of the morphology of the humerus and glenoid and malpositioning of the implant components can be prevented

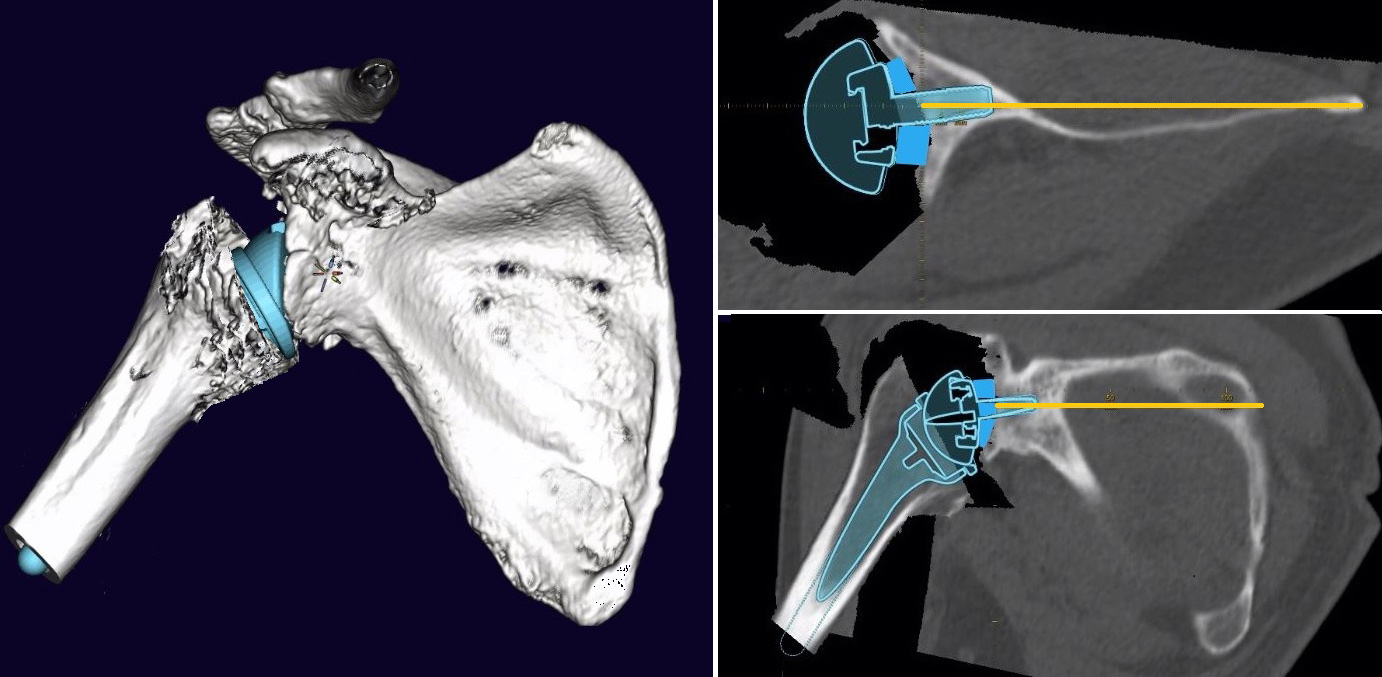

• 3D implant templates allow for placement in different positions on a 3D CT reconstruction of the patient

• Optimal simulation of the implant position to achieve the desired surgical goals faster and more successfully

The 3-dimensional planning also helps with the correct placement of the K-wire. The software shows virtually in frontal view the situation of the implant.

Originally, prototyping tools were common in the 1980s and were first used for industrial purposes and detailed reconstructions of complex sculptures during the early days. In the healthcare sector, development began in oral medicine and is known as MRP - Medical Rapid Prototyping, which is used in oral and maxillofacial surgery and neurosurgery.

Preoperative planning of the inverse shoulder prosthesis with mediCAD® 3D Shoulder

In orthopedic surgery, prototyping can be used for everything from malignant consolidations to the treatment of complex fractures and the planning of orthopedic inserts. An increasingly popular tool among orthopedic surgical teams, this technique consists of two stages: one virtual (three-dimensional image) and one physical (model fabrication). First, a computer-generated image of the structure under study is created, then the physical model is built by depositing synthetic material using laminates (CAD – computer-aided design).

Especially for surgical procedures such as the insertion of a shoulder prosthesis, mediCAD® 3D proves to be a preferred tool among orthopedic surgeons. Results from cooperative work between mediCAD® 3D and orthopedic surgical teams clearly show that the use of mediCAD® 3D in the area of preoperative planning of the inverse shoulder prosthesis has become increasingly popular in pre-operative planning. The tilt and morphological design can be determined by automatic measurement functions and alignment of the individual bone planes. Version and tilt can both be corrected by bony augmentation of the glenoid or by using an augmented baseplate or an eccentric glenosphere.

Win-win situation through the use of mediCAD®

With the help of the synthetic models generated by the mediCAD® 3D technique, the surgeon can perform more precise preoperative planning. The 3D implant templates allow the placement of implants in different positions in a 3D CT reconstruction of the patient during planning. By performing this technique on the model before surgery, the surgeon has optimal conditions along with a simulated implant position to achieve the desired surgical goals. The size and position of the component is chosen so that the humeral component does not interfere with the range of motion.

Supporting arguments for the use of mediCAD® in the preoperative planning of the inverse shoulder prosthesis are:

- mediCAD® 3D Shoulder helps support surgeons and the surgical team in gaining a better understanding of the configuration of the fracture or deformity; an idea of the depth of the structures that is not possible through traditional 2D imaging.

- Possibility to get a much better understanding of the lesion and perform the surgery on the model before performing it on the patient, which from the point of view of preoperative planning is not comparable to traditional drawings.

- Shortening of the operation time and thus reduction of blood loss and risk of infection; possibility of a more anatomical reconstruction; possibility of using the molds intraoperatively, as the material can be sterilized.

- Three-dimensional planning also helps with the correct placement of the K-wire.

In addition to a more detailed anatomical study, mediCAD® makes it possible to plan osteotomies before the surgical procedure and to reproduce them intraoperatively; it even allows determination of the size of the implants to be used and their insertion position, which reduces the surgical time and possible measurement errors.

Patient retention thanks to a positive experience is another factor for a successful economic future. Component sizes and position are chosen accurately to prevent impairment of the range of motion by the humeral component.

Conclusion about use of mediCAD® in inversive shoulder prosthesis field

Shoulder surgery is one of the procedures that has evolved the most in the last decade thanks to the evolution of diagnostic tools, such as mediCAD®. Especially in the use of shoulder prostheses, the development of materials that fit 1:1 is necessary. At the same time, there has also been a technical improvement on the part of physicians dedicated to the treatment of shoulder pathology. More and more orthopedic physicians are therefore specializing in shoulder pathology and the demand for suitable tools is increasing accordingly.

The use of mediCAD® 3D Shoulder is undoubtedly a useful method to reproduce bone changes in deformities and deviations of the proximal humerus and glenoid. Thus, it allows for more accurate preoperative planning and reduces complications that arise from the difficult three-dimensional understanding of such changes. The surgical advantages of preoperative planning of the inverse shoulder prosthesis are mainly to simplify the daily work of an already complex subject by precision modeling.